Impact of cycling on cathode tape

The NMC (Nickel-Manganese-Cobalt, LiNixMnyCo(1 – x – y)O2) cathodes currently occupy more than a half of the Li-Ion battery market and their share is expected to grow in the coming years because of their lower price and smaller ecological footprint compared to the previously utilised materials. They are also intensively researched as a suitable cathode material for future Solid-state batteries.

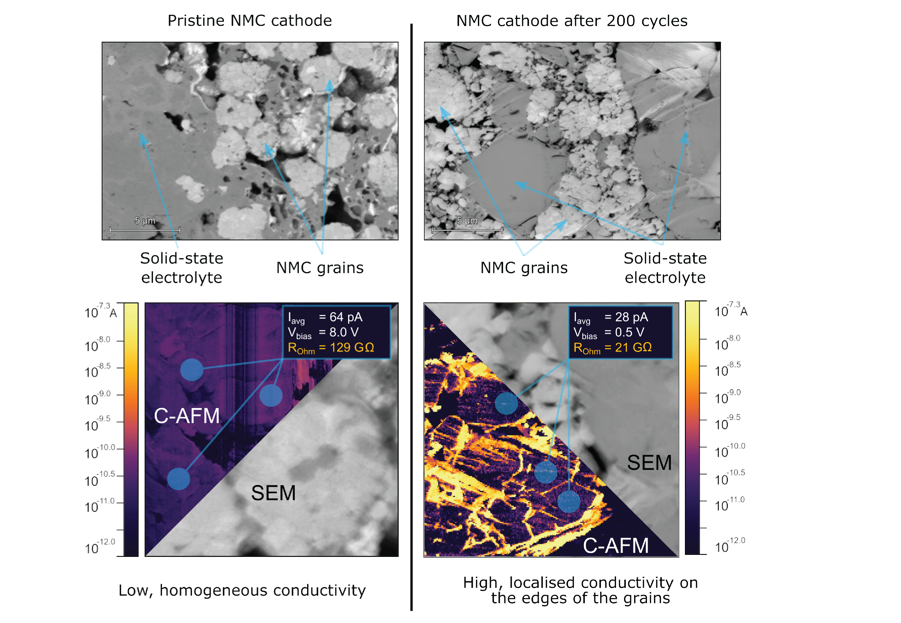

We have compared two types of samples prepared by the Broad Ion Beam. The first sample is a pristine NMC cathode tape, the second one is the tape material after 200 charge-discharge cycles.

The SEM reveals that the cycled cathode has observable cracks inside the NMC grains. LiteScope provides information about the local electrical properties of the samples. The most striking difference between them is the significant increase in conductivity at the edges of the NMC grains. Further evaluation reveals that the conductivity has also increased inside the grains.

Measurement modes: AFM topography, C-AFM, SEM

LiteScope benefits:

- No air-exposure or contamination

- Understanding the cycling effects without compromises

- Precise location of the region of interest

- Failure analysis from the combined C-AFM and SEM images supplemented by EDS data

Acknowledgement: Peter Priecel and Libor Novak, Thermo Fisher Scientific, and Ondrej Klvac, FEEC BUT

See also

Want to discuss your own application?