Battery Component Materials Analyses

Energy storage devices are crucial to today‘s technology. Understanding their features, performance, aging, and capacity is vital. Most high-end batteries are Li-ion, with active materials extremely susceptible to atmospheric contamination and degradation.

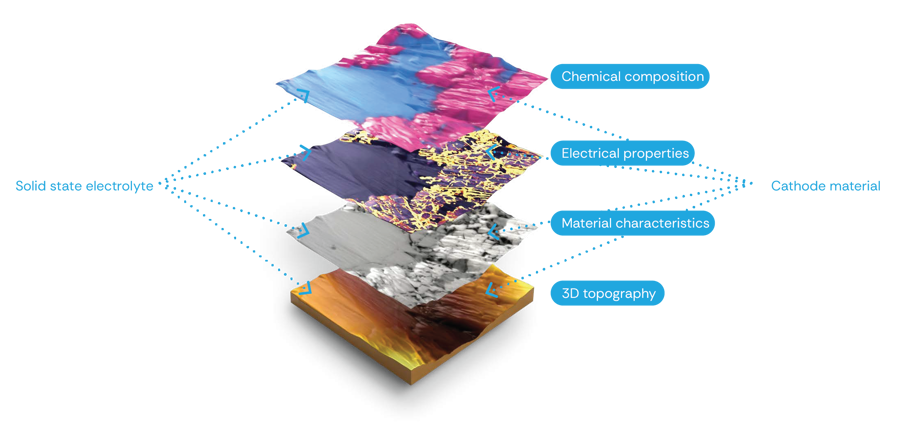

Our battery materials solution with AFM-in-SEM LiteScope provides a complete hardware and measurement workflow approach. It allows for an air-free sample transfer system that prevents contamination by oxygen and humidity, while ensuring uncompromised sample surface preparation. The imaging power of AFM-in-SEM provides a complex and site-specific understanding of the electrical and chemical properties of battery components.

Key Added Values

Site-specific local resistivity of individual particles

In-situ performance and degradation of battery components

Complementary to SEM analytical capabilities (FIB, EDX, etc.)

No air exposure of sensitive surfaces

Application areas

- Cell and battery components

- Raw active materials

- Cathodes

- Anodes

- Solid electrolytes

- Liquid electrolytes

Testimonials

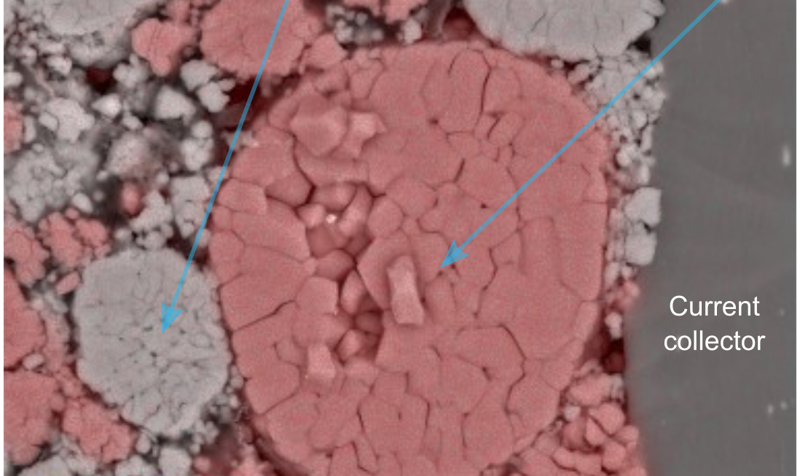

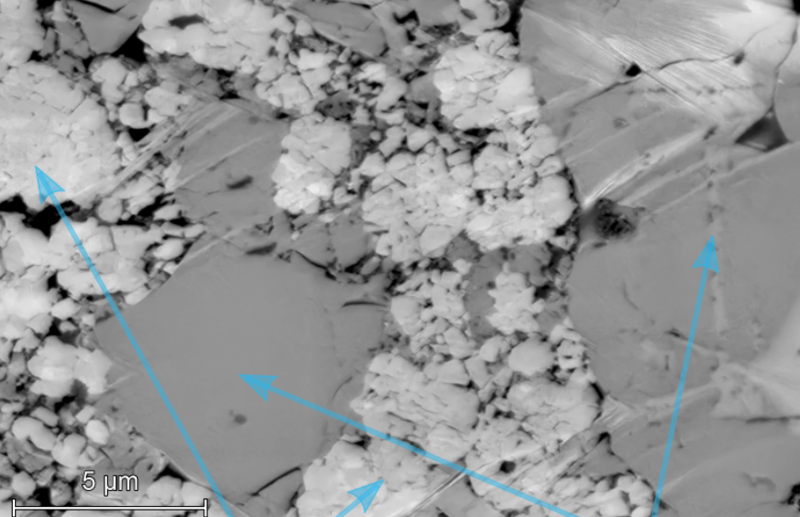

Thanks to LiteScope AFM-in-SEM technology, we can analyze the properties of active materials and their interactions with other parts of the electrode and electrolyte. This technology also allows us to better understand the degradation processes of electrode materials during cycling in terms of the interaction of individual grains of polycrystalline cathode materials at submicroscopic and microscopic levels. A better understanding of the degradation processes could help to prevent it and improve of the performance of the new types of Li-ion batteries.

We have been collaborating with the Nenovision team on SSB cathode analysis and have found their technology highly valuable for assessing conductivity together with SEM imaging. The insights from conductivity measurements have been crucial in evaluating the quality of SSB electrodes and their integrity after cycling. Additionally, the detailed surface morphology analysis offered by the Litescope has enabled us to identify microstructural changes post-cycling. We are convinced that the combination of SEM and AFM provided by Nenovision's Litescope device is essential for understanding battery performance and facilitating improvements in battery technology.

Measurement workflow

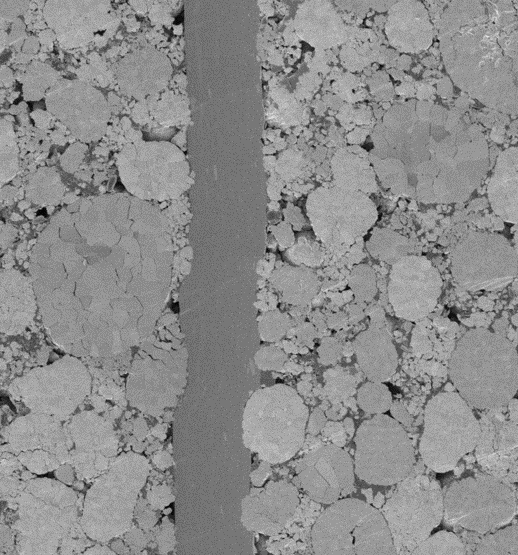

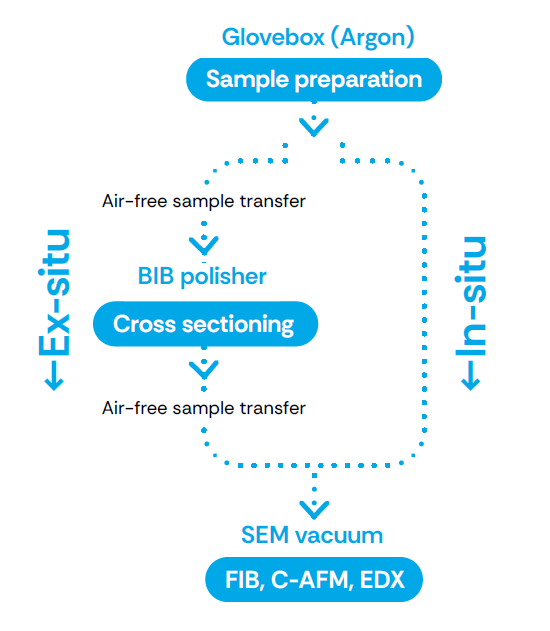

The battery materials, whether they are cathodes, solid-state electrolytes, or other components, are usually composed of particles of various sizes. To prepare samples suitable for AFM and SEM analysis, we use ion beam milling to create cross-sections of the specimens. The milling can be performed either ex-situ, outside the SEM in a dedicated Broad Ion Beam device, or in-situ, inside a dual-beam FIB-SEM microscope using a Focused Ion Beam. Since the battery samples are typically air-sensitive, the transfer between the Glovebox, Broad Ion Beam device, and SEM is conducted using a Sample Transfer Module.

1. Ex-situ sample preparation using Sample Transfer System

This option allows larger cross-section preparation in specialized instruments while maintaining the sample surface in the necessary environment, even during transfer

2. In-situ sample preparation using Focused Ion Beam

LiteScope enables safe AFM probe positioning for large stage tilts, preserving the tip from redeposition and allowing the use of FIB to cut a trench anywhere on the sample. This allows measurement of the uncovered surface using AFM-in-SEM technology.

Key Benefits and Features

Fast and easy sample transfer

Small evacuation time is needed to exchange the samples.

Air-sensitive samples are protected from surface contamination or oxidation in a vacuum or inert gas atmosphere at all times.

A comprehensive procedure for the cross-sectional analysis of complex battery components and materials testing.

Extended possibilities are enabled using FIB/GIS prep, AFM, C-AFM, KPFM, phase imaging, SE, BSE, EDX, Fz spectroscopy, …

Case studies

Webinar

Watch our webinar to delve deeper into the key benefits of employing AFM-in-SEM for the characterization of battery materials.

- Key challenges in the characterization of batteries and their components and how AFM-in-SEM technology resolves them.

- Efficient sample preparation workflow of extremely air-sensitive battery samples, their cross-sectioning, and sample transfer to integrated AFM/SEM/EDX instrument.

- Application examples of in-situ correlative microscopy analysis of various cathode materials (NCM, NCA) in pristine and cycled stages. We will demonstrate how AFM-in-SEM is used to understand the degradation process inside the cathodes.